想使用STM32G474VET6的TIM1(高级定时器)作为PWM输出控制三相电机,希望使用互补带死区功能CH1,CH1N,CH2,CH2N,CH3,CH3N。参考官方Demo和CubeMx,使用以下代码生成PWM

TIM_HandleTypeDef htim1;

void InitTimer1(void){

TIM_OC_InitTypeDef sConfigOC = {0};

TIM_ClockConfigTypeDef sClockSourceConfig = {0};

TIM_MasterConfigTypeDef sMasterConfig = {0};

TIM_BreakDeadTimeConfigTypeDef sBreakDeadTimeConfig = {0};

__HAL_RCC_TIM1_CLK_ENABLE();

htim1.Instance = TIM1;

htim1.Init.Prescaler = 0;

htim1.Init.CounterMode = TIM_COUNTERMODE_CENTERALIGNED2;

htim1.Init.Period = 4249; //170MHz / 20KHz / 2 - 1

htim1.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

htim1.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_DISABLE;

htim1.Init.RepetitionCounter = 0;

HAL_TIM_PWM_Init(&htim1);

sClockSourceConfig.ClockSource = TIM_CLOCKSOURCE_INTERNAL;

HAL_TIM_ConfigClockSource(&htim1, &sClockSourceConfig);

//TODO

sMasterConfig.MasterOutputTrigger = TIM_TRGO_RESET;

sMasterConfig.MasterOutputTrigger2 = TIM_TRGO2_RESET;

sMasterConfig.MasterSlaveMode = TIM_MASTERSLAVEMODE_DISABLE;

HAL_TIMEx_MasterConfigSynchronization(&htim1, &sMasterConfig);

sConfigOC.OCMode = TIM_OCMODE_PWM1; //CCMR1_OCxM

sConfigOC.Pulse = 300;

sConfigOC.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfigOC.OCNPolarity = TIM_OCNPOLARITY_HIGH;

sConfigOC.OCFastMode = TIM_OCFAST_DISABLE;

sConfigOC.OCIdleState = TIM_OCIDLESTATE_RESET;

sConfigOC.OCNIdleState = TIM_OCNIDLESTATE_RESET;

HAL_TIM_PWM_ConfigChannel(&htim1, &sConfigOC, TIM_CHANNEL_1);

HAL_TIM_PWM_ConfigChannel(&htim1, &sConfigOC, TIM_CHANNEL_2);

HAL_TIM_PWM_ConfigChannel(&htim1, &sConfigOC, TIM_CHANNEL_3);

__HAL_TIM_ENABLE_OCxPRELOAD(&htim1, TIM_CHANNEL_1);

__HAL_TIM_ENABLE_OCxPRELOAD(&htim1, TIM_CHANNEL_2);

__HAL_TIM_ENABLE_OCxPRELOAD(&htim1, TIM_CHANNEL_3);

HAL_TIM_PWM_Start(&htim1, TIM_CHANNEL_1);

HAL_TIMEx_PWMN_Start(&htim1, TIM_CHANNEL_1);

HAL_TIM_PWM_Start(&htim1, TIM_CHANNEL_2);

HAL_TIMEx_PWMN_Start(&htim1, TIM_CHANNEL_2);

HAL_TIM_PWM_Start(&htim1, TIM_CHANNEL_3);

HAL_TIMEx_PWMN_Start(&htim1, TIM_CHANNEL_3);

LL_TIM_GenerateEvent_UPDATE(TIM1);

}

static void SetSysClockTo170_HSE8(void){

__HAL_RCC_PWR_CLK_ENABLE();

__HAL_PWR_VOLTAGESCALING_CONFIG(PWR_REGULATOR_VOLTAGE_SCALE1_BOOST);

RCC_OscInitTypeDef RCC_OscInitStruct;

RCC_ClkInitTypeDef RCC_ClkInitStruct;

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSE;

RCC_OscInitStruct.HSEState = RCC_HSE_ON;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSE;

RCC_OscInitStruct.PLL.PLLM = RCC_PLLM_DIV2;

RCC_OscInitStruct.PLL.PLLN = 85; //8-127

RCC_OscInitStruct.PLL.PLLP = RCC_PLLP_DIV16;

RCC_OscInitStruct.PLL.PLLQ = RCC_PLLQ_DIV6;

RCC_OscInitStruct.PLL.PLLR = RCC_PLLR_DIV2;

if(HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK){

while(1);

}

/*The maximum frequency of the AHB, the APB1 and the APB2 domains is 170 MHz.*/

RCC_ClkInitStruct.ClockType = (RCC_CLOCKTYPE_SYSCLK | RCC_CLOCKTYPE_HCLK | RCC_CLOCKTYPE_PCLK1 | RCC_CLOCKTYPE_PCLK2);

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV1;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1;

if(HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_4) != HAL_OK){

while(1);

}

}

int main(void){

HAL_Init();

SetSysClockTo170_HSE8();

InitGpio();

InitTimer1();

//InitTimer1_LL();

while(1){

HAL_GPIO_TogglePin(GPIOC, GPIO_PIN_13);

HAL_Delay(250);

}

return 0;

}

void InitGpio(void){

__HAL_RCC_GPIOA_CLK_ENABLE();

__HAL_RCC_GPIOB_CLK_ENABLE();

__HAL_RCC_GPIOC_CLK_ENABLE();

__HAL_RCC_GPIOE_CLK_ENABLE();

GPIO_InitTypeDef GPIO_InitStruct;

GPIO_InitStruct.Pin = GPIO_PIN_13;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP; //推挽

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_HIGH;

HAL_GPIO_Init(GPIOC, &GPIO_InitStruct);

//LED Red-PE0 Green-PE1

GPIO_InitStruct.Pin = GPIO_PIN_0 | GPIO_PIN_1;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP; //推挽

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_HIGH;

HAL_GPIO_Init(GPIOE, &GPIO_InitStruct);

//upper bridge arm U-PA8 V-PA9 W-PA10

GPIO_InitStruct.Pin = GPIO_PIN_8 | GPIO_PIN_9 | GPIO_PIN_10;

GPIO_InitStruct.Mode = GPIO_MODE_AF_PP; //复用推挽

GPIO_InitStruct.Pull = GPIO_PULLDOWN;

GPIO_InitStruct.Speed = GPIO_SPEED_HIGH;

GPIO_InitStruct.Alternate = GPIO_AF6_TIM1;

HAL_GPIO_Init(GPIOA, &GPIO_InitStruct);

//lower bridge arm U-PB13 V-PB14

GPIO_InitStruct.Pin = GPIO_PIN_13 | GPIO_PIN_14;

GPIO_InitStruct.Mode = GPIO_MODE_AF_PP; //复用推挽

GPIO_InitStruct.Pull = GPIO_PULLDOWN;

GPIO_InitStruct.Speed = GPIO_SPEED_HIGH;

GPIO_InitStruct.Alternate = GPIO_AF6_TIM1;

HAL_GPIO_Init(GPIOB, &GPIO_InitStruct);

//lower bridge arm W-PB15

GPIO_InitStruct.Pin = GPIO_PIN_15;

GPIO_InitStruct.Mode = GPIO_MODE_AF_PP; //复用推挽

GPIO_InitStruct.Pull = GPIO_PULLDOWN;

GPIO_InitStruct.Speed = GPIO_SPEED_HIGH;

GPIO_InitStruct.Alternate = GPIO_AF4_TIM1;

HAL_GPIO_Init(GPIOB, &GPIO_InitStruct);

}

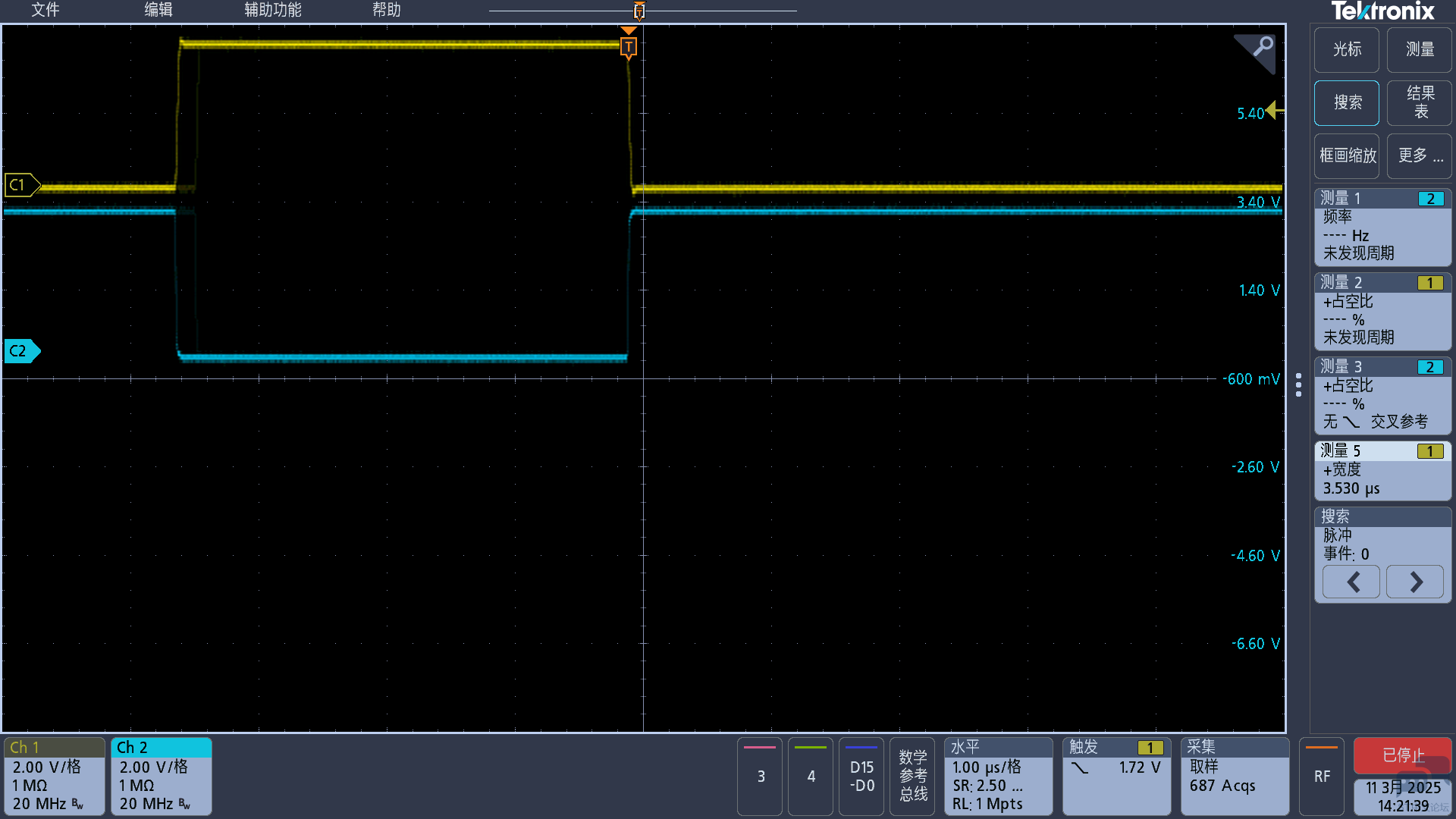

经过测试,发现在使能输出以后,正脉冲宽度会有波动,在示波器上可以看出明显余晖,如下图所示,按照代码设计,PWM频率应为20KHz,占空比约为7.06%,正脉冲宽度约为3.529us,大部分波形符合预期。

小部分波形脉冲宽度仅为3.375us,缩小画面后发现波形异常时PWM频率为20.06KHz

使用示波器脉冲宽度小于阈值触发多个波形可以发现,正常波形占大多数,异常波形不会连续出现(下图图片上方白色倒三角为搜索正脉冲宽度小于3.4us的波形所在位置)

通过查阅手册以及在开发板上测试,发现仅开启一组互补输出时,不会发生该现象,如仅开启CH1,CH1N;开启两组及两组以上互补输出时,会发生该现象;计数器使用上升或下降模式(边沿)计数时,不会发生该现象;使用上下模式(中心对称)计数时会产生此现象。

已尝试的方法还有

1、使用LL库

2、修改HAL库,修改外设使能顺序,MOE,UG寄存器使能顺序

3、去掉死区

以上方法均不能解决该问题,请求各位帮助👀️

微信公众号

微信公众号

手机版

手机版

不过板子上用的是24MHZ 晶振。

昨晚我看见您的回复以后,连夜又贴了两块板子。今早测试发现确实是MCU的问题。十分感谢您的测试,截图和回复🎉️