- 代码的基本逻辑:目前只是使用了电流环,我们设定目标

Iq_set = 0.3,然后调用PID控制函数,返回值传给Uq

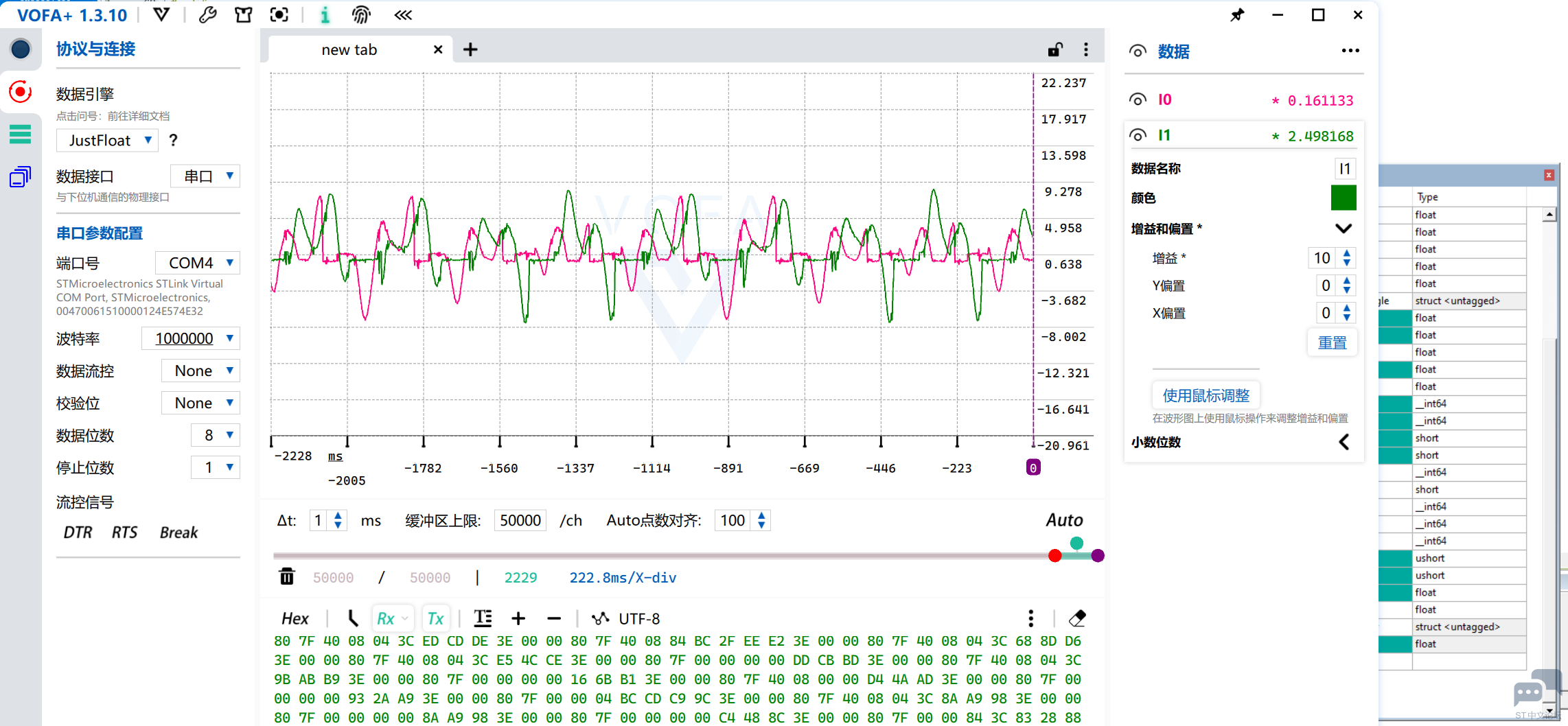

- 目前存在的问题:肉眼观察下电机可以正常的转动,但是高负载的情况下转不动。目前通过调试观察 Iq 的值,发现Iq根本无法稳定在 0.3 附近,而且无规律的跳动。使用上位机观察UWV其中两项的电流值,电流曲线有点正弦波的样子,但是很杂。搞了很长时间找不出问题在哪里,求指导。

typedef struct

{

float error; // 当前误差

float errorLast; // 上一次误差

float feedforward; // 前馈

float integral; // 积分

float saturation; // 饱和

float differ; // 差值

float kp; // 比例增益

float ki; // 积分增益

float kd; // 微分增益

float ns; // 速度限制

float ka; // 加速度限制

float limit; // 限制

} PID_LocTypeDef;

/* 初始化PID参数 */

PID_Init(&PID_Iq, 0.65, 0.12, 0, 10, 0.01);foc.Uq = PID_Loc(0.3, cur.Iq, &PID_Iq);

void PID_Init(PID_LocTypeDef* pidHandle, float kp, float ki, float kd, float limit, float ns)

{

pidHandle->kp = kp;

pidHandle->ki = ki;

pidHandle->kd = kd;

pidHandle->limit = limit;

pidHandle->ns = ns;

}

foc.Uq = PID_Loc(0.3, cur.Iq, &PID_Iq);

setPhaseVoltage(&foc, angle.Eangle);

这是foc的SVPWM代码

// FOC核心函数:输入Ud、Uq和电角度,输出PWM

void setPhaseVoltage(sfoc *foc, float angle)

{

foc->angle_el = angle;

foc->angle_el = _normalizeAngle(foc->angle_el);

float cos_angle = arm_cos_f32(foc->angle_el);

float sin_angle = arm_sin_f32(foc->angle_el);

// 反park变换

foc->U_alpha = foc->Ud * cos_angle - foc->Uq * sin_angle;

foc->U_beta = foc->Ud * sin_angle + foc->Uq * cos_angle;

foc->Uref = _sqrtf(foc->U_alpha * foc->U_alpha + foc->U_beta * foc->U_beta) / voltage_power_supply;

// 限制最大参考电压

if (foc->Uref > 0.577f)

foc->Uref = 0.577f;

if (foc->Uref < -0.577f)

foc->Uref = -0.577f;

// 标准化电角度值,并根据Uq确定扇区

if (foc->Uq > 0)

foc->angle_el = _normalizeAngle(foc->angle_el + _PI_2);

else

foc->angle_el = _normalizeAngle(foc->angle_el - _PI_2);

foc->sector = (foc->angle_el / _PI_3) + 1;

// 计算作用时间

foc->T1 = SQRT_3 * arm_sin_f32(foc->sector * _PI_3 - foc->angle_el) * foc->Uref;

foc->T2 = SQRT_3 * arm_sin_f32(foc->angle_el - (foc->sector - 1.0f) * _PI_3) * foc->Uref;

foc->T0 = 1 - foc->T1 - foc->T2;

// 根据扇区计算占空比

switch (foc->sector) {

case 1:

foc->Ta = foc->T1 + foc->T2 + foc->T0 / 2;

foc->Tb = foc->T2 + foc->T0 / 2;

foc->Tc = foc->T0 / 2;

break;

case 2:

foc->Ta = foc->T1 + foc->T0 / 2;

foc->Tb = foc->T1 + foc->T2 + foc->T0 / 2;

foc->Tc = foc->T0 / 2;

break;

case 3:

foc->Ta = foc->T0 / 2;

foc->Tb = foc->T1 + foc->T2 + foc->T0 / 2;

foc->Tc = foc->T2 + foc->T0 / 2;

break;

case 4:

foc->Ta = foc->T0 / 2;

foc->Tb = foc->T1 + foc->T0 / 2;

foc->Tc = foc->T1 + foc->T2 + foc->T0 / 2;

break;

case 5:

foc->Ta = foc->T2 + foc->T0 / 2;

foc->Tb = foc->T0 / 2;

foc->Tc = foc->T1 + foc->T2 + foc->T0 / 2;

break;

case 6:

foc->Ta = foc->T1 + foc->T2 + foc->T0 / 2;

foc->Tb = foc->T0 / 2;

foc->Tc = foc->T1 + foc->T0 / 2;

break;

default: // 错误情况

foc->Ta = 0;

foc->Tb = 0;

foc->Tc = 0;

break;

}

// 输出PWM信号

TIM1->CCR1 = foc->Ta * PWM_PERIOD;

TIM1->CCR2 = foc->Tb * PWM_PERIOD;

TIM1->CCR3 = foc->Tc * PWM_PERIOD;

}

这是PID控制的代码

float PID_Loc(float SetValue, float ActualValue, PID_LocTypeDef* pidHandle)

{

pidHandle->error = SetValue - ActualValue;

/* Proportional Item */

float p = pidHandle->kp * pidHandle->error;

/* Integral Item */

float i = pidHandle->ki * (pidHandle->error - pidHandle->ka * pidHandle->saturation) + pidHandle->integral;

// i = _constrain(i, MIN(0.f, -pidHandle->limit), MAX(0.f, pidHandle->limit));

i = _constrain(i, -pidHandle->limit, pidHandle->limit);

pidHandle->integral = i;

/* Differential Item */

float d = pidHandle->kd * pidHandle->ns * (pidHandle->error - pidHandle->errorLast) -

pidHandle->differ * (pidHandle->ns - 1.0f);

pidHandle->errorLast = pidHandle->error;

pidHandle->differ = d;

/* Output value update and saturation value calculation */

float val = p + i + d + pidHandle->feedforward;

float out = _constrain(val, -pidHandle->limit, pidHandle->limit);

pidHandle->saturation = val - out;

return out;

}

这是计算Iq和Id的值部分

void HAL_ADCEx_InjectedConvCpltCallback(ADC_HandleTypeDef *hadc)

{

GetCurrent(&cur);

float I_alpha = cur.CurA;

float I_beta = (cur.CurB - cur.CurC) * SQRT_3 / 2;

cur.Id = I_alpha * arm_cos_f32(foc.angle_el) + I_beta * arm_sin_f32(foc.angle_el);

cur.Iq = I_beta * arm_cos_f32(foc.angle_el) - I_alpha * arm_sin_f32(foc.angle_el);

/* 低通滤波 */

cur.Id = LowPassFilter_Update(&LPF_Id, cur.Id);

cur.Iq = LowPassFilter_Update(&LPF_Iq, cur.Iq);

}

这是使用上位机观察到了UV两项的电流波形。

在调试中观察的数值变化

微信公众号

微信公众号

手机版

手机版

目前我感觉是PID函数没有在正常的工作

1.检测电流环PI参数是否合适;

2.电流环控制是否只控制了Q轴,而没有控制D轴电流,如果是话,请把D轴也加上;

3、检查采样电流是否正确;

4.可以参考ST的 MCSDK的相关代码;

好的我会继续尝试不同的PI参数。目前只控制Q轴,d周我直接赋值

Ud = 0,电流采样部分应该是没什么问提。